‘Car Concept’ is regularly mentioned when bodywork is changed on a Formula One car. Visual differences that are clear to see. But does that accurately reflect what a team means by a ‘car concept’?

For the answer, it’s worth rewinding a little. Let’s look at the basics of F1 car design. Understanding how cars generate performance and the factors involved in making that happen.

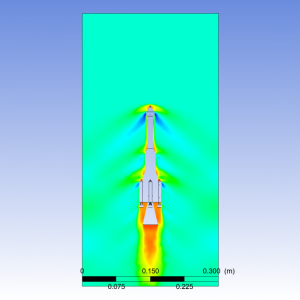

In F1, there are three key technical elements that generate car performance: tyres, power unit, and aerodynamics. We have an influence over all of them, but the biggest differentiator of the three is the aerodynamics. And when we talk about aero, we’re not just talking about the shape of the car and the bodywork.

It’s also about how we use the car, how we control the car, how we evolve the balance and set-up to work with the aero package. Because those factors also impact the aerodynamic performance on track.

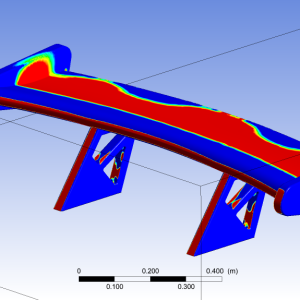

The most influential element of an aerodynamic package is the front wing because it’s the first piece of the car that hits the air. It’s also one of the most visually striking differences to the car, along with the sidepods and rear wing, when we bring a new specification.

However, the area of the car that generates the most downforce is hidden from view: the floor. The rest of the bodywork still makes a difference and influences how the downforce is generated across the car and from the floor, but the majority of the performance comes from the floor and wings.

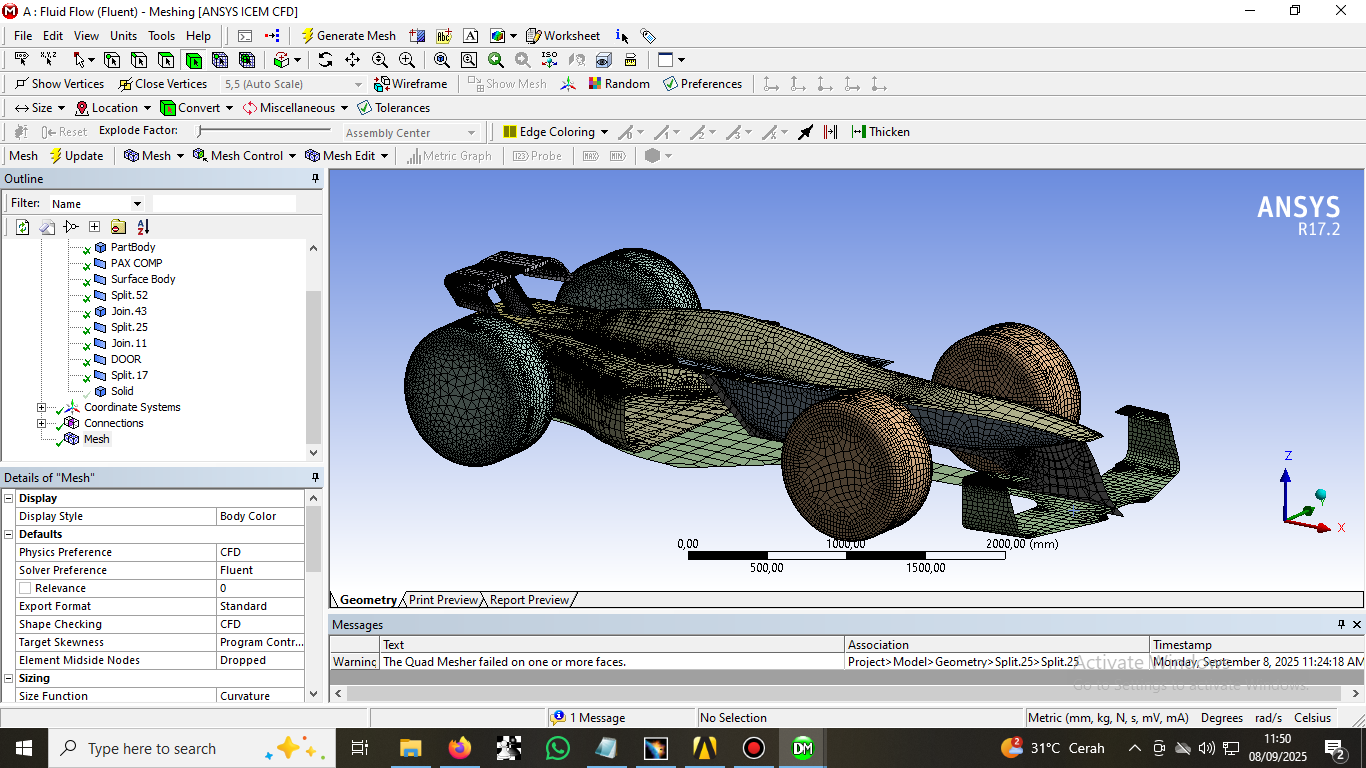

What is Meshing ?

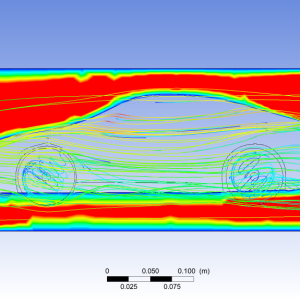

Meshing is the process of dividing a complex 2D or 3D geometric shape into a network of smaller, simpler, commented shapes called elements. This discretization creates a “mesh” of nodes (points) and elements that transforms the continuous geometry into a numerical model suitable for computer simulation, like finite element analysis (FEA). The purpose is to enable computers to solve equations and simulate physical phenomena, such as stress or fluid flow, by applying simple mathematical rules to these smaller, manageable pieces.

- Discretization: The continuous geometry is broken down into a grid of smaller elements.

- Elements: These elements are geometric shapes, such as triangles and quadrilaterals for 2D surfaces, or tetrahedrons and hexahedrons for 3D volumes.

- Nodes: Each element contains nodes, which are coordinate points in space that represent the boundaries of the elements.

- Simulation: These interconnected nodes and elements form a mesh, which serves as the input for simulation software, allowing it to analyze the physical behavior of the object.

- Simplification of Complex Geometry: It turns complex, irregular shapes into recognizable volumes, making them understandable to computers.

- Numerical Analysis: It is a fundamental step in methods like FEA, which require a numerical model to solve partial differential equations that describe physical behavior.

- Predictive Power: Meshing enables engineers to simulate and predict how a structure or system will perform under various conditions, aiding in informed design decisions.

- Element Size: Smaller elements and a finer mesh generally lead to more accurate results but require more computational power and time.

- Element Type: Hexahedral (hex) elements often provide more accurate results with fewer elements than tetrahedral (tet) elements, though tets may be better suited for very complex geometries.

- Mesh Independence: The goal is often to reach a state of mesh independence, where increasing the number of elements no longer significantly changes the simulation’s results

Reviews

There are no reviews yet.