The Design – Ethylene Glycol + Water Liquid Through Car Radiator Cooling System | Ansys Fluent

This simulation is about an Analysis of Ethylene Glycol + Water Liquid Through Car Radiator Cooling System using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

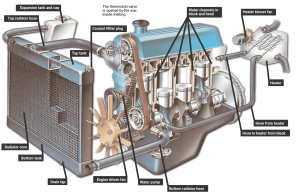

A car’s radiator cooling system circulates coolant to absorb heat from the engine and dissipate it into the air. This process involves a water pump to circulate the coolant, a thermostat to regulate its flow, and a radiator with fins and a fan to cool the liquid before it returns to the engine. The entire system works continuously to keep the engine at an optimal operating temperature.

Picture 1. A car’s radiator cooling system

Components and function

- Coolant: A mixture of water and antifreeze that absorbs heat from the engine.

- Water Pump: Circulates the coolant through the engine and the radiator. It’s typically driven by a belt.

- Thermostat: Controls the coolant’s flow. It remains closed when the engine is cold to help it warm up, and opens to allow coolant to flow to the radiator once the engine reaches its proper operating temperature.

- Radiator: The main heat exchanger. Hot coolant enters the radiator, flows through its fins, and transfers heat to the air passing through.

- Radiator Fan: Sits behind the radiator to pull air through the fins, especially at low speeds or when stopped. Some systems use a fan clutch that engages based on temperature, while others use electric fans.

- Hoses: Carry the coolant between the engine, radiator, and other components like the heater core.

How the system works

- Heat absorption: The water pump sends coolant through channels in the engine block, where it absorbs heat.

- Thermostat regulation: The hot coolant is pushed to the radiator. If the engine is cold, the thermostat stays closed, and the coolant circulates within the engine block to warm it up faster.

- Heat dissipation: Once the engine is warm, the thermostat opens. The hot coolant flows into the radiator’s upper tank, then through small tubes with fins. Air flowing through these fins (either from the car’s movement or the fan) removes heat from the coolant.

- Recirculation: The now-cooled coolant exits the radiator and returns to the engine via the water pump to repeat the cycle.

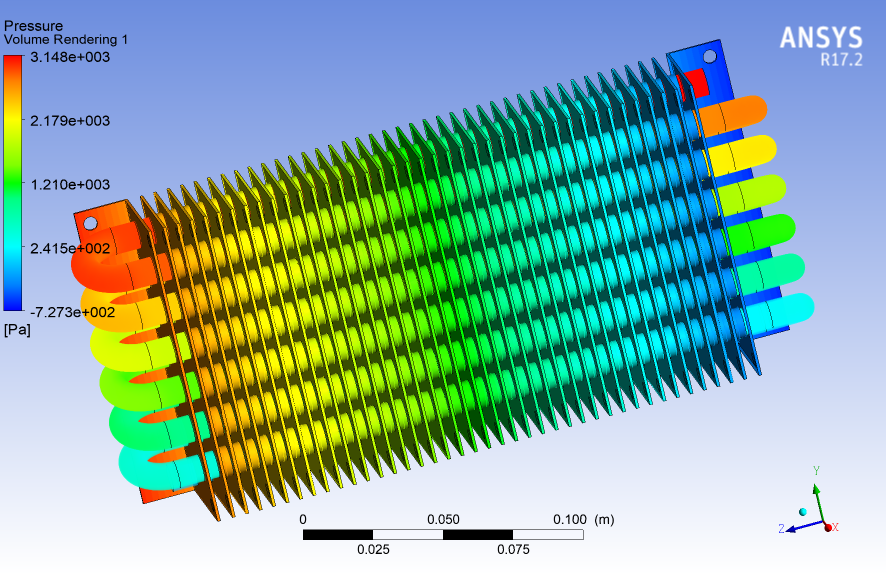

In this analysis, it has been made to simulate and analyze Ethylene Glycol + Water Liquid Through Car Radiator Cooling System using ANSYS Fluent software.

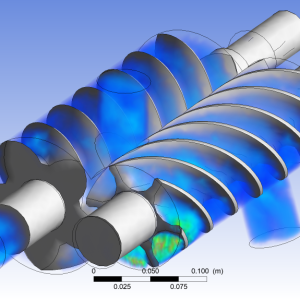

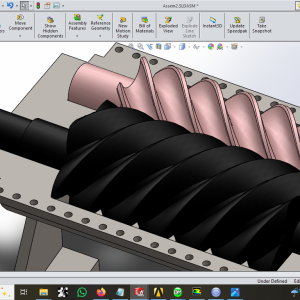

Geometry & Grid

The geometry required for flow analysis in a car radiator is produced by ANSYS Fluent software. The generated grid is also produced by the same software for this geometry, which is entirely of an unstructured type. The total number of volume properties for geometry is 4,9112e+005 mm³.

Model

For analysis of the mixture process, a Reynolds Stress (7 eqn) viscous model is used to simulate fluid flow. Linear Pressure-Strain has been used for the Reynolds-Stress Model. Standard Wall Functions are used for Near-Wall Treatment.

Boundary Condition

The flow input for this analysis is defined as the VELOCITY INLET for input supersonic/initial gauge pressure is 101325 pascal. Velocity magnitude for Ethylene Glycol is 0.5 m/s. The walls of the car Radiator are defined as Stationary Wall for Wall Motion. The output flow type is PRESSURE OUTLET, and the gauge pressure is equal to 0.

Discretization of Equations

According to the type of flow, the Coupled algorithm is used to discretize the Pressure-Velocity Coupling of the solution method. The turbulent kinetic energy and the turbulent dissipation rate has been discretized in the Second Order Upwind.

The results are presented as pressure contours as well as volume rendering.

The Design Services

We also accept all CFD projects using ANSYS Fluent and ANSYS CFX. Our workshop has gathered experts in different engineering fields so as to ensure the quality of CFD simulations. One of our objectives is to boost the use of powerful computational fluid dynamics methods and also teach the engineers and those who seek professional knowledge in CFD.

ِDoing CFD projects will be faster and easier with our services. Call us for training in CFD applications and CFD packages. Our professional CFD engineers offer you professional consultation and technical supports for your academic CFD projects and industrial CFD projects. We offer you CFD learning, CFD project by ANSYS Fluent and ANSYS CFX, CFD consulting by ANSYS Fluent and ANSYS CFX, CFD service by ANSYS Fluent and ANSYS CFX, ANSYS Fluent and ANSYS CFX project, ANSYS Fluent and ANSYS CFX thesis, ANSYS Fluent and ANSYS CFX simulation, ANSYS Fluent and ANSYS CFX paper regeneration, ANSYS Fluent and ANSYS CFX academic project, ANSYS Fluent and ANSYS CFX industrial project, ANSYS Fluent, and ANSYS CFX research project, and low CFD Price. Moreover, we have years of experience in coordinating CFD projects. Therefore, we are ready to perform your CFD simulations in different engineering fields.

Reviews

There are no reviews yet.