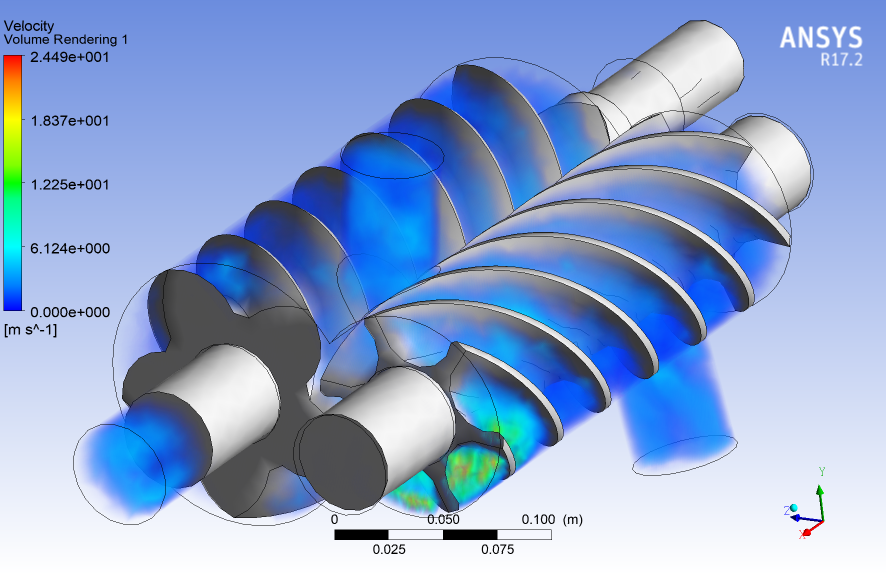

The Design – 3D Rotating Simulation Twin Screw Compressor | Ansys CFX

This simulation is about a 3D Rotating Simulation Twin Screw Compressor using ANSYS CFX software. We perform this CFD project and investigate it by CFD analysis.

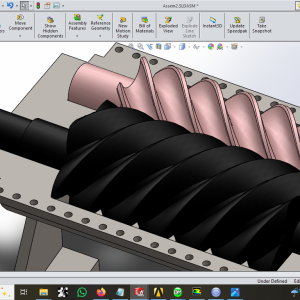

A twin-screw compressor is a positive displacement rotary machine with two inter-meshing helical rotors that draw in and compress a fluid, like air, as it moves through the device. The rotors are contained within a casing, and as they turn, the space between them and the casing shrinks, trapping and compressing the fluid until it is discharged. These compressors are known for their efficiency, reliability, and versatility in various industrial applications, and can be oil-injected or oil-free.

Picture 1. Twin-Screw Compressors

How it works

- Suction: Gas is pulled into the space between the rotors through an inlet port.

- Compression: As the rotors turn, the spaces between the helical lobes become progressively smaller, which compresses the trapped gas.

- Discharge: The compressed gas is expelled from the end of the rotors through an outlet port.

Key components

- Rotors: Two helical rotors, a male and a female, that intermesh to perform the compression. The female rotor typically has more lobes than the male rotor.

- Casing: Encloses the rotors and the entire compression process.

- Timing gears: Synchronize the rotation of the rotors to keep them from touching, ensuring proper operation.

- Lubrication system: For oil-injected versions, oil is used for cooling, lubrication, and sealing the rotors.

Types

- Oil-injected: Oil is injected into the compression chamber to help with cooling, sealing, and lubrication.

- Oil-free: No oil is injected into the compression chamber, making the discharged air suitable for applications where oil contamination is a concern.

Advantages

- Efficiency: They are known for high energy efficiency and a steady, continuous output of compressed air.

- Reliability: They have a stable and reliable performance, with many models built to handle high pressures and varying load conditions.

- Versatility: They can be used for various gases and in different industrial settings, including those with high temperature, high humidity, or corrosive gases.

- Compact size: Their compact structure saves space in industrial applications.

In this analysis, it has been made to simulate and analysis of 3D Rotating Simulation Twin Screw Compressor using ANSYS CFX software.

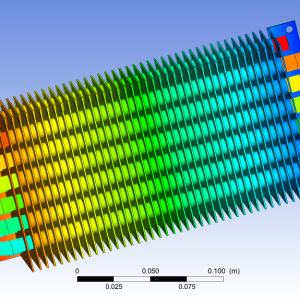

Geometry & Grid

The geometry required for this analysis was generated by the Ansys Design Modeler software. The meshing required for this analysis was also generated by Ansys Meshing software. The mesh type used in this analysis is unstructured. The total number of volume properties for geometry is 1,6043e+007 mm³.

Model

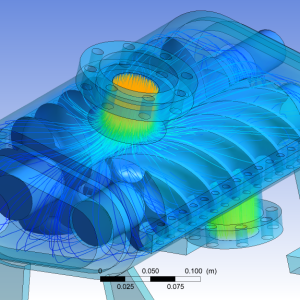

In this analysis, a transient analysis type was used to obtain the results to check the fluid flow. In this analysis, buoyant models have been used, and stationary domain motion has also been activated in this analysis.

Boundary Condition

The flow input for this geometry of a Twin Screw Compressor that directs the flow of water at a fluid temperature of 25°C into the geometry. The turbulence boundary condition of a Twin Screw Compressor wall is considered to be k-Epsilon according to the working conditions. The wall function is defined as Scalable in the name selection section of turbulence boundary condition. The static pressure for the design modeler is set as relative pressure equal to 1 Pa.

Discretization of Equations

In this analysis, high resolution is used for the advection scheme of the basic settings. In this analysis, the first-order is used for turbulence numerics. In this analysis, the residual type of convergence criteria is RMS, and the residual target of convergence criteria is 0,0001.

The results are presented as velocity contours as well as volume rendering.

The Design Services

We also accept all CFD projects using ANSYS Fluent and ANSYS CFX. Our workshop has gathered experts in different engineering fields so as to ensure the quality of CFD simulations. One of our objectives is to boost the use of powerful computational fluid dynamics methods and also teach the engineers and those who seek professional knowledge in CFD.

ِDoing CFD projects will be faster and easier with our services. Call us for training in CFD applications and CFD packages. Our professional CFD engineers offer you professional consultation and technical supports for your academic CFD projects and industrial CFD projects. We offer you CFD learning, CFD project by ANSYS Fluent and ANSYS CFX, CFD consulting by ANSYS Fluent and ANSYS CFX, CFD service by ANSYS Fluent and ANSYS CFX, ANSYS Fluent and ANSYS CFX project, ANSYS Fluent and ANSYS CFX thesis, ANSYS Fluent and ANSYS CFX simulation, ANSYS Fluent and ANSYS CFX paper regeneration, ANSYS Fluent and ANSYS CFX academic project, ANSYS Fluent and ANSYS CFX industrial project, ANSYS Fluent, and ANSYS CFX research project, and low CFD Price. Moreover, we have years of experience in coordinating CFD projects. Therefore, we are ready to perform your CFD simulations in different engineering fields.

Reviews

There are no reviews yet.