The Design – Analysis of Turbulent Air Flow Over Monument | ANSYS Fluent

This simulation is about an Analysis of Turbulent Air Flow Over Monument using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

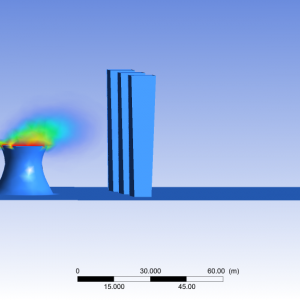

- Pressure distribution: Turbulent airflow creates varying pressure distributions over the monument’s surface. High-velocity winds result in high pressures on the windward side and suction (low pressure) on the leeward side and roof.

- Wind loads: The force exerted by the wind (wind load) can cause vibration, material fatigue, and in extreme cases, structural failure. The analysis helps determine the maximum expected wind load for engineering and preservation purposes.

- Vortex shedding: As air flows past a monument, it can create vortices (swirling air pockets) that shed alternately from the sides. This can cause the monument to oscillate or “gallop,” leading to structural damage over time, a phenomenon known as vortex-induced vibration.

- Pollutant dispersion: Airflow patterns, including recirculation zones and eddies created by the monument’s shape, can trap and concentrate air pollutants near the structure. These pollutants can accelerate the decay of the monument’s materials.

- Material erosion: The abrasive effect of high-velocity, turbulent air can erode a monument’s surfaces over time, especially if the air carries dust or other particulates.

- Moisture transport: Airflow patterns can affect how moisture interacts with the monument. Areas of recirculation can trap moisture, promoting biological growth, while other areas may experience increased drying, which can lead to cracking.

- Interaction with surrounding structures: The turbulent wake created by a monument can influence the airflow patterns of surrounding buildings and urban areas, and vice versa. This is a critical consideration in urban planning to ensure adequate ventilation and prevent the concentration of pollutants.

- Pedestrian comfort: The complex flow patterns around monuments, especially tall ones, can create high-velocity wind zones at ground level, impacting pedestrian comfort and safety.

- Computational Fluid Dynamics (CFD): Numerical simulations are a primary tool for modeling turbulent airflow over monuments.

- Modeling: CFD uses mathematical models to simulate the behavior of fluids. For turbulent flow, models like the k-ε and k-ω models are commonly used to predict velocity fields, pressure distribution, and turbulence intensity.

- Validation: CFD results are often validated against experimental data from wind tunnel tests or field measurements to ensure accuracy.

- Wind tunnel testing: Physical models of the monument are placed in a controlled wind tunnel environment to measure airflow characteristics and forces.

- Measurements: Advanced instruments like hot-wire anemometers are used to measure velocity, turbulence, and pressure at different points around the model.

- Scaling: Proper scaling laws must be applied to extrapolate the results from the model to the full-scale monument.

- Field measurements: Sensors are placed directly on or around the monument to collect real-world data on wind speed, direction, and turbulence. This provides an important baseline for validating theoretical models and simulations.

- Separation and reattachment: Airflow separates from the monument’s surface at sharp corners or curvatures, creating a wake region behind it. Further downstream, the flow may reattach to the surface, creating complex recirculation zones.

- Recirculation regions: These are areas behind the monument where the air flows in the reverse direction, creating a low-pressure zone. These zones can trap pollutants and contribute to structural issues.

- Boundary layer effects: The atmospheric boundary layer, with its varying wind speed and turbulence, significantly influences how the flow interacts with the monument. The monument’s height relative to the boundary layer thickness is an important factor.

This analysis has tried to simulate and analyze of Turbulent Air Flow Over Monument using ANSYS Fluent software.

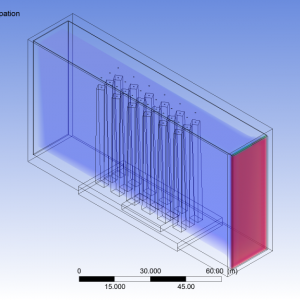

Geometry & Grid

The geometry required for this analysis was generated by Ansys Design Modeler software. The meshing required for this analysis was also generated by Ansys Meshing software. The mesh type used in this analysis is unstructured. The total number of volume properties for geometry is 1,4401e+012 mm³.

Model

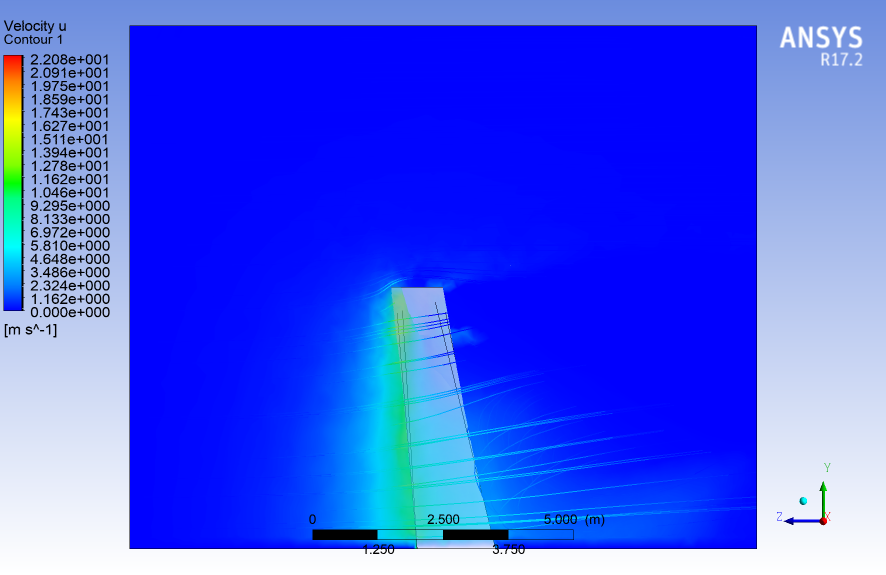

In this analysis, the k-epsilon (2 equation) turbulence viscosity model is used to check the fluid flow. The standard wall function is used near the wall.

Boundary Condition

The flow of primary input design modeler geometry for this analysis is considered as velocity magnitude and is 22.3 (m/s). The flow output range is also considered as a pressure outlet for the flow output region and gauge pressure is equal to 0 (pascal). The wall is also considered a Stationary Wall.

Sizing

According to the type of flow, the Coupled algorithm is used to discretize the Pressure-Velocity Coupling of the solution method. The turbulent kinetic energy and the turbulent dissipation rate has been discretized in the Second Order Upwind.

The results are presented as velocity u contours as well as streamlines.

The Design Services

We also accept all CFD projects using ANSYS Fluent and ANSYS CFX. Our workshop has gathered experts in different engineering fields so as to ensure the quality of CFD simulations. One of our objectives is to boost the use of powerful computational fluid dynamics methods and also teach the engineers and those who seek professional knowledge in CFD.

ِDoing CFD projects will be faster and easier with our services. Call us for training in CFD applications and CFD packages. Our professional CFD engineers offer you professional consultation and technical supports for your academic CFD projects and industrial CFD projects. We offer you CFD learning, CFD project by ANSYS Fluent and ANSYS CFX, CFD consulting by ANSYS Fluent and ANSYS CFX, CFD service by ANSYS Fluent and ANSYS CFX, ANSYS Fluent and ANSYS CFX project, ANSYS Fluent and ANSYS CFX thesis, ANSYS Fluent and ANSYS CFX simulation, ANSYS Fluent and ANSYS CFX paper regeneration, ANSYS Fluent and ANSYS CFX academic project, ANSYS Fluent and ANSYS CFX industrial project, ANSYS Fluent, and ANSYS CFX research project, and low CFD Price. Moreover, we have years of experience in coordinating CFD projects. Therefore, we are ready to perform your CFD simulations in different engineering fields.

Reviews

There are no reviews yet.