The Design – Ethylene Glycol + Water Liquid Through 2D Radiator | Ansys Fluent

This simulation is about an Analysis of Ethylene Glycol + Water Liquid Through 2D Radiator using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

Radiator (engine cooling)

Radiators are heat exchangers used for cooling internal combustion engines, mainly in automobiles but also in piston-engined aircraft, railway locomotives, motorcycles, stationary generating plants or any similar use of such an engine.

Internal combustion engines are often cooled by circulating a liquid called engine coolant through the engine block and cylinder head where it is heated, then through a radiator where it loses heat to the atmosphere, and then returned to the engine. Engine coolant is usually water-based, but may also be oil. It is common to employ a water pump to force the engine coolant to circulate, and also for an axial fan to force air through the radiator.

Picture 1. A typical engine coolant radiator used in an automobile

Automobiles and motorcycles

In automobiles and motorcycles with a liquid-cooled internal combustion engine, a radiator is connected to channels running through the engine and cylinder head, through which a liquid (coolant) is pumped by a coolant pump. This liquid may be water (in climates where water is unlikely to freeze), but is more commonly a mixture of water and antifreeze in proportions appropriate to the climate. Antifreeze itself is usually ethylene glycol or propylene glycol (with a small amount of corrosion inhibitor).

A typical automotive cooling system comprises:

- a series of galleries cast into the engine block and cylinder head, surrounding the combustion chambers with circulating liquid to carry away heat;

- a radiator, consisting of many small tubes equipped with a honeycomb of fins to dissipate heat rapidly, that receives and cools hot liquid from the engine;

- a water pump, usually of the centrifugal type, to circulate the coolant through the system;

- a thermostat to control temperature by varying the amount of coolant going to the radiator;

- a fan to draw cool air through the radiator.

The combustion process produces a large amount of heat. If heat were allowed to increase unchecked, detonation would occur, and components outside the engine would fail due to excessive temperature. To combat this effect, coolant is circulated through the engine where it absorbs heat. Once the coolant absorbs the heat from the engine it continues its flow to the radiator. The radiator transfers heat from the coolant to the passing air.

Radiators are also used to cool automatic transmission fluids, air conditioner refrigerant, intake air, and sometimes to cool motor oil or power steering fluid. A radiator is typically mounted in a position where it receives airflow from the forward movement of the vehicle, such as behind a front grill. Where engines are mid- or rear-mounted, it is common to mount the radiator behind a front grill to achieve sufficient airflow, even though this requires long coolant pipes. Alternatively, the radiator may draw air from the flow over the top of the vehicle or from a side-mounted grill. For long vehicles, such as buses, side airflow is most common for engine and transmission cooling and top airflow most common for air conditioner cooling.

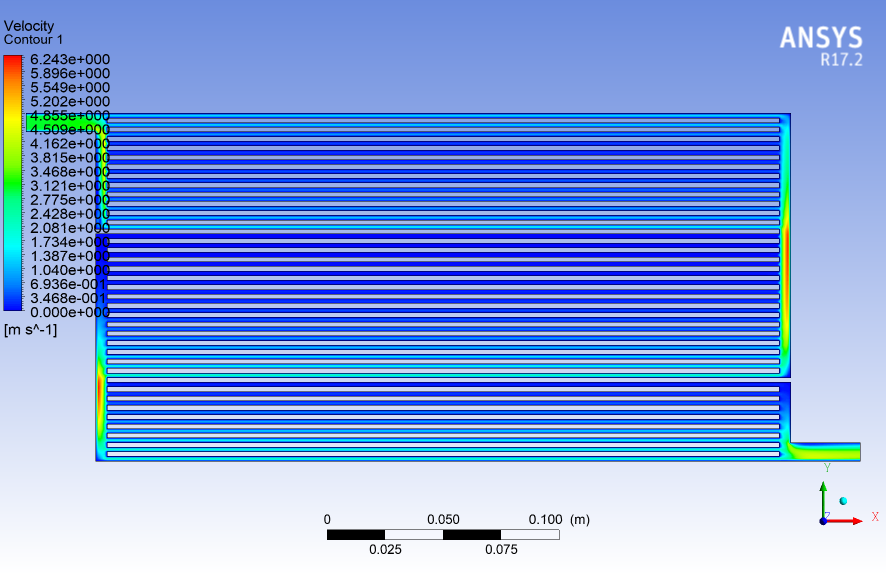

In this analysis, it has been made to simulate and analyze Ethylene Glycol + Water Liquid Through 2D Radiator using ANSYS Fluent software.

Geometry & Grid

The geometry required for flow analysis in a 2D Radiator body is produced by ANSYS Fluent software. The generated grid is also produced by the same software for this geometry, which is entire of an unstructured type. The total number of volume properties for geometry is 24000 mm².

Model

For analysis of the mixture process, a Reynolds Stress (7 eqn) viscous model is used to simulate fluid flow. Linear Pressure-Strain has been used for the Reynolds-Stress Model. Standard Wall Functions are used for Near-Wall Treatment.

Boundary Condition

The flow input for this analysis is defined as the VELOCITY INLET for input supersonic/initial gauge pressure is 101325 pascal. Velocity magnitude for Ethylene Glycol is 3 m/s, and volume fraction for multiphase is 1. The walls of the 2D Radiator are defined as Stationary Wall for Wall Motion. The output flow type is PRESSURE OUTLET, and the gauge pressure is equal to 0.

Discretization of Equations

The SIMPLE algorithm is used to solve the equations in this analysis. Also, a pressure-based solver for flow is used. The First Order Upwind method has been used to discretize equations. First-Order Upwind is used only for the discretization of the momentum equations.

In the end, the results are shown as velocity contours.

The Design Services

We also accept all CFD projects using ANSYS Fluent and ANSYS CFX. Our workshop has gathered experts in different engineering fields so as to ensure the quality of CFD simulations. One of our objectives is to boost the use of powerful computational fluid dynamics methods and also teach the engineers and those who seek professional knowledge in CFD.

ِDoing CFD projects will be faster and easier with our services. Call us for training in CFD applications and CFD packages. Our professional CFD engineers offer you professional consultation and technical supports for your academic CFD projects and industrial CFD projects. We offer you CFD learning, CFD project by ANSYS Fluent and ANSYS CFX, CFD consulting by ANSYS Fluent and ANSYS CFX, CFD service by ANSYS Fluent and ANSYS CFX, ANSYS Fluent and ANSYS CFX project, ANSYS Fluent and ANSYS CFX thesis, ANSYS Fluent and ANSYS CFX simulation, ANSYS Fluent and ANSYS CFX paper regeneration, ANSYS Fluent and ANSYS CFX academic project, ANSYS Fluent and ANSYS CFX industrial project, ANSYS Fluent, and ANSYS CFX research project, and low CFD Price. Moreover, we have years of experience in coordinating CFD projects. Therefore, we are ready to perform your CFD simulations in different engineering fields.

Reviews

There are no reviews yet.