The Design – Cylindrical 2D CFD Analysis of Fluid Flow Over a Bluff Body | ANSYS Fluent

This simulation is about a Cylindrical 2D CFD Analysis of Fluid Flow Over a Bluff Body using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

A two-dimensional (2D) Computational Fluid Dynamics (CFD) analysis of a bluff body, such as a cylinder, investigates the unsteady flow behavior around it, including vortex shedding, wake structures, and pressure distributions, to predict aerodynamic forces like drag and lift. Key parameters like Reynolds number (Re) dictate the flow regime (laminar or turbulent), and the finite volume method (FVM) with algorithms like SIMPLE is a common approach to discretize the flow domain and solve the governing equations for this unsteady flow.

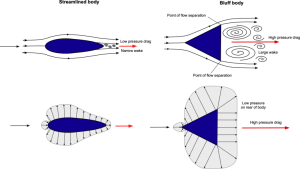

The differences in the flows between a streamlined body and a bluff body. The bluff body produces flow separation and a large, broad wake, characterized by low pressures, resulting in high drag.

The physics behind the simulation

The flow behavior around a cylinder is highly dependent on the Reynolds number ![]() , a dimensionless quantity that characterizes the flow regime.

, a dimensionless quantity that characterizes the flow regime.

![]() Where:

Where:

is the fluid density

is the fluid density is the fluid velocity

is the fluid velocity is the cylinder diameter

is the cylinder diameter is the dynamic viscosity of the fluid

is the dynamic viscosity of the fluid

Depending on the Reynolds number, the flow can be:

- Low Reynolds number

: The flow is steady and laminar, and a pair of stable, symmetric vortices form behind the cylinder.

: The flow is steady and laminar, and a pair of stable, symmetric vortices form behind the cylinder. - Intermediate Reynolds number

: The flow becomes unsteady. The symmetric vortices begin to shed alternately from the top and bottom of the cylinder, creating a pulsating flow known as a von Kármán vortex street.

: The flow becomes unsteady. The symmetric vortices begin to shed alternately from the top and bottom of the cylinder, creating a pulsating flow known as a von Kármán vortex street. - High Reynolds number

: The flow becomes fully turbulent. The point of flow separation moves further downstream, leading to a smaller, more turbulent wake.

: The flow becomes fully turbulent. The point of flow separation moves further downstream, leading to a smaller, more turbulent wake.

This analysis has tried to simulate and analyze Cylindrical 2D CFD Analysis of Fluid Flow Over a Bluff Body using ANSYS Fluent software.

Geometry & Grid

The geometry required for this analysis was generated by Ansys Design Modeler software. The meshing required for this analysis was also generated by Ansys Meshing software. The mesh type used in this analysis is Face Meshing. The total number of surface area (approx.) properties for geometry is 1,3964e+005 mm².

Model

In this analysis, the laminar viscosity model is used to check the fluid flow.

Boundary Condition

The flow of primary input design modeler geometry for this analysis is considered as velocity magnitude and is 10 (m/s). The flow output range is also considered as a pressure outlet for the flow output region and gauge pressure is equal to 0 (pascal). The top wall and bottom wall is also considered a Stationary Wall.

Sizing

According to the type of flow, the Coupled algorithm is used to discretize the Pressure-Velocity Coupling of the solution method. The momentum equation has been discretized in the Second Order Upwind.

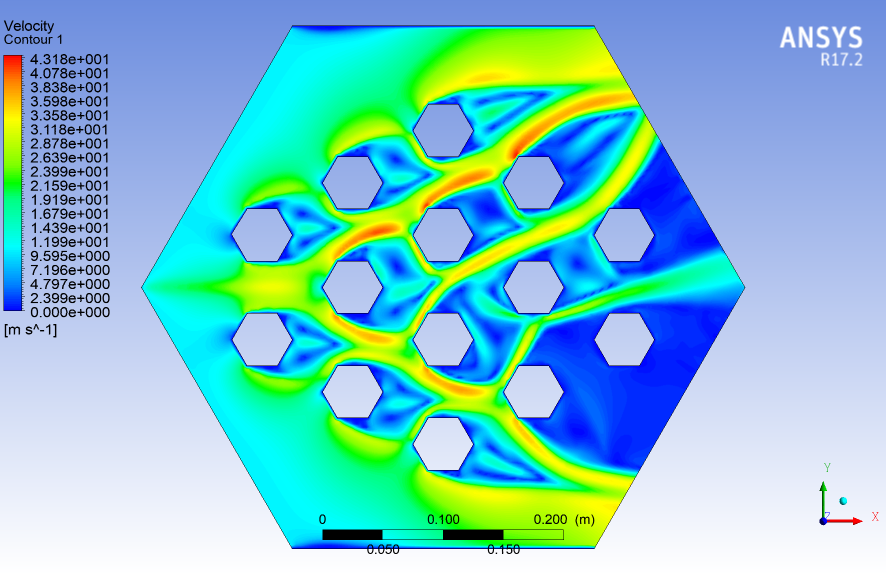

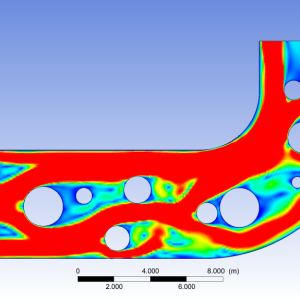

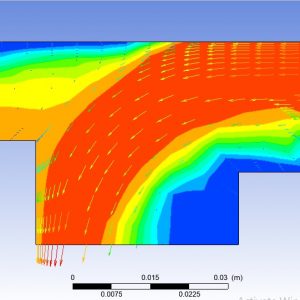

The results are presented as velocity contours as well as streamlines.

The Design Services

We also accept all CFD projects using ANSYS Fluent and ANSYS CFX. Our workshop has gathered experts in different engineering fields so as to ensure the quality of CFD simulations. One of our objectives is to boost the use of powerful computational fluid dynamics methods and also teach the engineers and those who seek professional knowledge in CFD.

ِDoing CFD projects will be faster and easier with our services. Call us for training in CFD applications and CFD packages. Our professional CFD engineers offer you professional consultation and technical supports for your academic CFD projects and industrial CFD projects. We offer you CFD learning, CFD project by ANSYS Fluent and ANSYS CFX, CFD consulting by ANSYS Fluent and ANSYS CFX, CFD service by ANSYS Fluent and ANSYS CFX, ANSYS Fluent and ANSYS CFX project, ANSYS Fluent and ANSYS CFX thesis, ANSYS Fluent and ANSYS CFX simulation, ANSYS Fluent and ANSYS CFX paper regeneration, ANSYS Fluent and ANSYS CFX academic project, ANSYS Fluent and ANSYS CFX industrial project, ANSYS Fluent, and ANSYS CFX research project, and low CFD Price. Moreover, we have years of experience in coordinating CFD projects. Therefore, we are ready to perform your CFD simulations in different engineering fields.

Reviews

There are no reviews yet.