The Design – Von Karman Effect over 12 Circular Cylinders | ANSYS Fluent

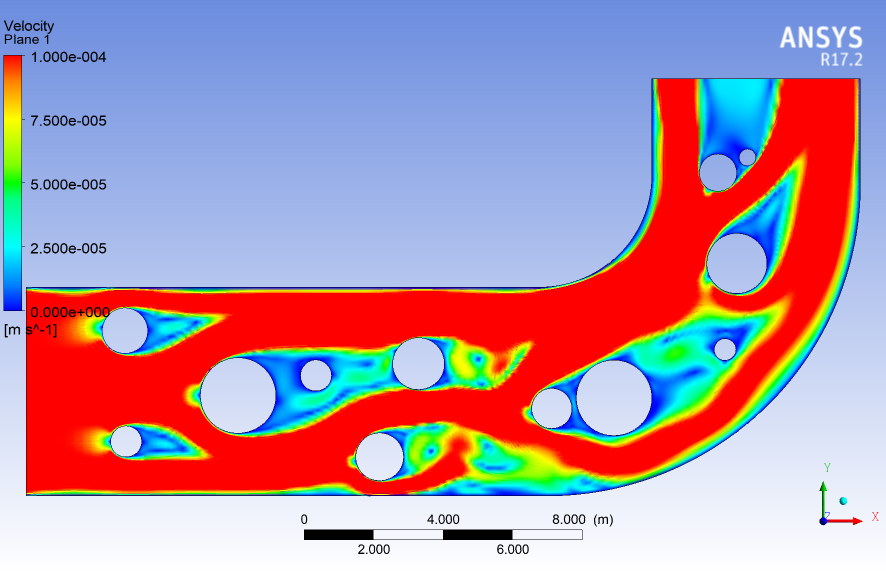

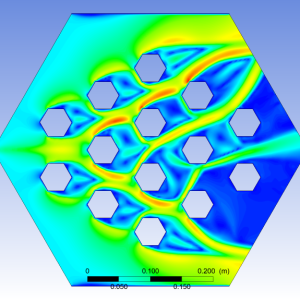

This simulation is about a Von Karman Effect over 12 Circular Cylinders using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

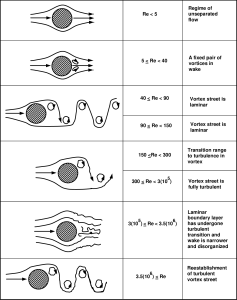

Table 1. Regimes of Fluid Flow Across Circular Cylinders

- Single-bluff-body (SBB) regime: If the cylinders are placed very close together, the cluster can behave like a single, larger bluff body. The flow does not pass through the array but is deflected around the entire group, and a single, coherent von Kármán vortex street forms downstream.

- Co-shedding (CS) regime: In a less densely packed arrangement, the flow can pass through the gaps between the cylinders. In this case, the cylinders influence each other, and their individual wakes may combine or synchronize to form larger, more complex vortex structures in the far-wake.

- Transitional (TR) regime: For intermediate spacing, the flow can exhibit characteristics of both the SBB and CS regimes, where wake patterns are highly complex and can transition between different modes.

- Cylinder arrangement: The specific layout of the 12 cylinders is crucial. An array of cylinders arranged in concentric rings, for example, will produce different flow dynamics than a linear or square pattern.

- One experimental study on arrays with different arrangements, including staggered and concentric, showed that increasing the number of cylinders and density can significantly alter the overall flow characteristics.

- Hydrodynamic interference: A key aspect of flow over multiple cylinders is the interference between the wake of upstream cylinders and the flow around downstream cylinders. This can:

- Alter the point of flow separation on downstream cylinders.

- Cause complex shielding effects where some cylinders experience reduced drag.

- Change the vortex-shedding frequency and force on individual cylinders.

- Total drag and forces: The combined effect of multiple wakes can lead to significantly different overall drag and fluctuating forces on the entire cylinder array compared to a single cylinder. Some arrangements may experience constructive or destructive interference of vortex shedding, leading to either stronger or weaker overall forces.

A study using numerical simulations explored the flow through and around a localized circular array of cylinders with varying numbers of cylinders (7 to 133). While not exactly 12, the results are relevant. For an array of 12 cylinders arranged in concentric rings, the simulations would likely show:

- A blockage effect where some flow is deflected around the array.

- A “bleeding” of flow through the spaces between the cylinders.

- The formation of complex wake structures influenced by the interaction of individual cylinder wakes.

- The ability to classify the flow behavior as either single-bluff-body, co-shedding, or transitional, depending on the spacing of the cylinders.

This analysis has tried to simulate and analyze the Von Karman Effect over 12 Circular Cylinders using ANSYS Fluent software.

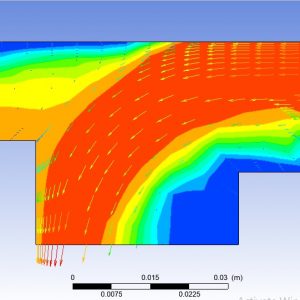

Geometry & Grid

The geometry required for this analysis was generated by Ansys Design Modeler software. The meshing required for this analysis was also generated by Ansys Meshing software. The mesh type used in this analysis is Face Meshing. The total number of surface area (approx.) properties for geometry is 1,4683e+008 mm².

Model

In this analysis, the laminar viscosity model is used to check the fluid flow.

Boundary Condition

The flow of primary input design modeler geometry for this analysis is considered as velocity magnitude and is 0.0001 (m/s). The flow output range is also considered as a pressure outlet for the flow output region and gauge pressure is equal to 0 (pascal). The wall is also considered a Stationary Wall.

Sizing

According to the type of flow, the SIMPLE algorithm is used to discretize the Pressure-Velocity Coupling of the solution method. The momentum equation has been discretized in the Second Order Upwind.

The results are presented as velocity contours as well as streamlines.

The Design Services

We also accept all CFD projects using ANSYS Fluent and ANSYS CFX. Our workshop has gathered experts in different engineering fields so as to ensure the quality of CFD simulations. One of our objectives is to boost the use of powerful computational fluid dynamics methods and also teach the engineers and those who seek professional knowledge in CFD.

ِDoing CFD projects will be faster and easier with our services. Call us for training in CFD applications and CFD packages. Our professional CFD engineers offer you professional consultation and technical supports for your academic CFD projects and industrial CFD projects. We offer you CFD learning, CFD project by ANSYS Fluent and ANSYS CFX, CFD consulting by ANSYS Fluent and ANSYS CFX, CFD service by ANSYS Fluent and ANSYS CFX, ANSYS Fluent and ANSYS CFX project, ANSYS Fluent and ANSYS CFX thesis, ANSYS Fluent and ANSYS CFX simulation, ANSYS Fluent and ANSYS CFX paper regeneration, ANSYS Fluent and ANSYS CFX academic project, ANSYS Fluent and ANSYS CFX industrial project, ANSYS Fluent, and ANSYS CFX research project, and low CFD Price. Moreover, we have years of experience in coordinating CFD projects. Therefore, we are ready to perform your CFD simulations in different engineering fields.

Reviews

There are no reviews yet.